In the dynamic world of printing technologies, UV DTF, or Direct to Film, stands out as a revolutionary advancement that is transforming creative possibilities. This innovative method harnesses the power of ultraviolet printing technology to deliver high-resolution prints on an impressive array of substrates, including textiles, metal, and wood. As we delve into how UV DTF works, you’ll discover the myriad benefits it offers—from durability to eco-friendly options. The versatility of UV DTF truly sets it apart, allowing for applications in various industries—from apparel production to custom promotional items. Join us as we explore the fascinating insights and applications of UV DTF that are reshaping the landscape of modern printing.

Also referred to as ultraviolet direct-to-film printing, this cutting-edge technology employs advanced curing processes to set inks on different surfaces with precision. The robustness of ultraviolet direct printing ensures that designs not only look vibrant but also endure the rigors of daily use. Industries ranging from fashion to interior design are finding that incorporating UV DTF allows them to create customized products that resonate with consumers. Moreover, this innovative printing solution provides an eco-friendly alternative with minimized waste and energy consumption. With the continuous evolution of techniques within the realm of UV DTF, the potential applications appear almost limitless.

Understanding How UV DTF Works

UV DTF, or Direct to Film, operates with a unique methodology that sets it apart from traditional printing techniques. The process begins with printing the desired design onto a specialized film using UV-cured inks. These inks are then instantly cured by exposure to ultraviolet light, ensuring that the colors remain vibrant and true. This immediate process eliminates the need for drying time, which is a common drawback in other printing methods. Once the design has been successfully transferred to the film, the next step involves transferring it to the final substrate using heat and pressure, resulting in high-resolution prints.

The capability of UV DTF technology to print on a diverse range of materials—from textiles to metal and wood—enhances its appeal significantly. This versatility allows for creative applications across numerous industries, catering to a range of market demands. Furthermore, the integration of high-quality UV inks ensures that the final product retains its integrity over time, offering resistance against scratches, fading, and peeling. Thus, UV DTF stands out as a formidable option within the realm of contemporary printing technology.

Benefits of Using UV DTF Technology

The benefits of UV DTF technology are manifold, making it an attractive choice for both commercial and personal projects. Firstly, its versatility allows it to function effectively across various applications, from creating promotional products to fashion accessories. This adaptability means that businesses can utilize the same technology to produce a wide range of items without having to invest in multiple printing solutions. Additionally, the direct application of UV inks ensures that prints are durable, preventing common issues such as wear and tear that would typically plague standard printed materials.

Moreover, the high-resolution output provided by UV DTF printing enables creators to produce intricate designs that captivate audiences. This technology not only supports vibrant colors but also allows for complex patterns that can enhance product appeal. Another notable benefit is the eco-friendliness associated with many UV inks today, which are formulated to reduce their environmental impact. This aspect resonates well with modern consumers who increasingly favor environmentally responsible products.

Recent Innovations in UV DTF Technology

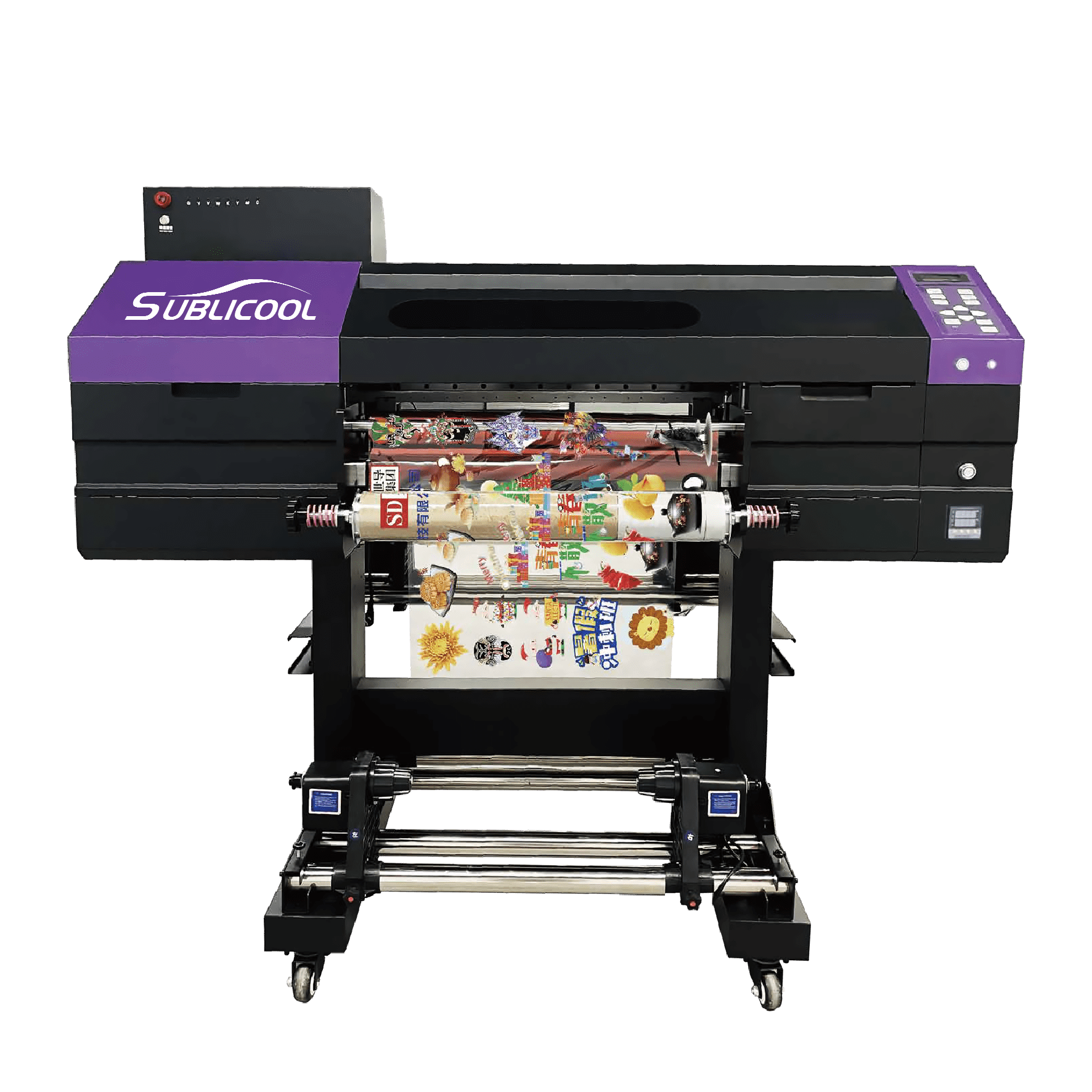

The landscape of UV DTF technology is characterized by a constant stream of innovations that drive the industry forward. One of the standout developments is the introduction of compact UV printers tailored for creative makers. These printers are not only portable but also equipped to handle intricate designs across various surfaces, expanding the horizons for hobbyists and professional creators alike. This trend indicates a growing interest among craft enthusiasts for high-quality, versatile printing tools that can deliver outstanding results.

Additionally, the emergence of groundbreaking products, such as the personal 3D texturing UV printer known as the E1, exemplifies how UV printing technology is evolving. By allowing users to print on numerous surfaces, including non-traditional materials, such devices pave the way for unique creative expressions. Such innovations showcase the broad potential of UV DTF, making it not just a method for producing prints, but a catalyst for artistic experimentation and personal branding in various markets.

Applications of UV DTF in Diverse Industries

The applications of UV DTF technology are extensive, spanning from promotional products to personalized fashion items. Businesses are leveraging this technology to create high-quality, custom merchandise that stands out in the crowded market space. For instance, promotional items like branded mugs, custom t-shirts, and unique giveaways can be produced with striking designs that effectively engage customers and foster brand loyalty. The ability to produce small runs of customized items is particularly appealing for companies aiming to connect with niche audiences.

In the fashion industry, UV DTF technology is revolutionizing how apparel is designed and produced. Custom clothing brands are utilizing this method to create vibrant, intricately designed pieces that resonate with contemporary fashion trends. The versatility of UV DTF allows for easy adaptation to various textiles, providing fashion designers with a tool that enhances creativity and enables rapid market responsiveness. Similarly, interior design professionals are harnessing this technology to customize furniture and home décor elements, allowing for a tailored approach to interior aesthetics.

Comparing UV DTF to Traditional Printing Methods

When comparing UV DTF to traditional printing methods, several key differences become apparent. Traditional methods, such as screen printing or dye-sublimation, often come with limitations when it comes to material compatibility and print durability. On the other hand, UV DTF excels by offering the capacity to print on a wide array of materials, including unconventional surfaces that traditional methods might struggle with. Moreover, UV DTF’s immediate curing process reduces total production time, leading to faster turnaround for projects.

Furthermore, UV DTF technology elevates print quality with its capacity to deliver stunning, high-definition prints. Traditional methods typically cannot match the color vibrancy and detail offered by UV DTF technology, making it a superior choice for intricate designs. As businesses continue to seek unique and high-quality products, UV DTF is positioned as a leading option in the printing landscape, demonstrating both adaptability and innovation.

The Future of UV DTF Technology

Looking ahead, the future of UV DTF technology appears bright as more businesses recognize its extensive potential. Continuous advancements in UV printing technology suggest that we can expect increasingly sophisticated equipment and better materials, which will further enhance print quality and ease of use. Innovations may pave the way for even more customizable solutions that cater to individual preferences, allowing for greater expression in both personal and commercial projects.

As the industry shifts towards more sustainable practices, the development of environmentally-friendly inks and processes will likely continue to grow. With a focus on eco-conscious production, UV DTF technology is expected to align well with market demands, appealing to consumers who prioritize sustainability. Overall, UV DTF technology stands at the forefront of printing evolution, promising to reshape how we create and perceive printed media in the years to come.

Frequently Asked Questions

How does UV DTF printing technology work?

UV DTF (Direct to Film) printing technology works by utilizing ultraviolet light to cure specially formulated inks on a transfer film. The process involves printing a design on this film, which is later transferred onto various substrates, including textiles and metal, using heat and pressure. This innovative technique allows for high-resolution prints that are durable and vibrant.

What are the main benefits of using UV DTF technology for printing?

The benefits of UV DTF technology include its versatility to print on various materials, durability against fading and scratches, and the ability to produce high-resolution prints with stunning color details. Additionally, many UV DTF inks are eco-friendly, making this technology a sustainable choice in printing.

What applications can UV DTF technology be used for?

UV DTF technology is applied in numerous sectors, including the creation of promotional products, custom apparel like t-shirts and bags, and interior design items. Its ability to print on diverse materials makes it a valuable tool for businesses and creatives looking for high-quality, customized printing solutions.

How has recent innovation impacted UV DTF printing technology?

Recent innovations in UV DTF printing technology, such as the introduction of compact and personal 3D texturing UV printers, have significantly enhanced the accessibility and functionality of this printing method. These advancements allow users to create more intricate designs on a wider range of surfaces, catering to evolving market demands.

What distinguishes UV DTF from traditional printing methods?

What distinguishes UV DTF from traditional printing methods is its use of UV light to cure inks, resulting in faster drying times and superior durability. Unlike conventional methods that may use solvent or water-based inks that require longer drying times, UV DTF prints are instantly cured, leading to immediate usability and enhanced image quality.

Is UV DTF an eco-friendly printing option?

Yes, UV DTF is considered an eco-friendly printing option as many modern UV inks are formulated to reduce environmental impact. They emit fewer volatile organic compounds (VOCs) compared to traditional inks, making UV DTF a sustainable choice that aligns with growing consumer preferences for eco-conscious products.

| Feature | Description |

|---|---|

| Technology Type | UV DTF (Direct to Film) uses ultraviolet light to cure ink on various substrates. |

| Versatility | Can print on a wide range of materials for various applications. |

| Durability | UV-cured inks resist fading, scratching, and peeling. |

| High Resolution Print Quality | Delivers stunning detail and vibrant colors for intricate designs. |

| Eco-Friendly Options | Many modern UV inks minimize environmental impact. |

Summary

UV DTF (Direct to Film) technology has transformed the printing industry with its innovative approach to high-resolution and durable printing across various substrates. By utilizing ultraviolet light for curing inks, UV DTF stands out by offering exceptional versatility, making it suitable for many applications, from promotional items to interior design. As advancements continue to roll out, such as personal 3D texturing printers and efficient printing platforms, UV DTF is paving the way for a more creative and accessible future in printing, appealing to professionals and hobbyists alike. Its eco-friendly options cater to the conscious consumer, further solidifying UV DTF’s place in the modern crafting landscape.