DTF transfers, or Direct-to-Film transfers, have revolutionized the world of personal apparel and custom item creation. This innovative technology provides DIY enthusiasts and crafters the opportunity to achieve professional-quality printing right from the comfort of home. With the ability to create vibrant and durable designs, DTF transfers are suitable for a wide range of fabrics, making them an ideal choice for t-shirts, tote bags, and more. If you’ve ever wondered how to DTF transfers at home, you’ll find that with the right equipment—especially a heat press for DTF transfers—you can produce stunning results that rival commercial prints. Join us as we explore the ins and outs of DIY DTF printing, sharing tips and insights to help you succeed in your creative endeavors.

In the realm of custom fabric printing, Direct-to-Film (DTF) technology has emerged as a preferred method for achieving detailed and colorful designs on various textiles. Often synonymous with terms like digital film transfer, this technique eliminates the limitations faced by traditional printing methods, allowing for creative expression across diverse fabric types. Enthusiasts and small businesses are increasingly drawn to print on-demand solutions, leveraging the efficiency of DTF prints to bring their unique designs to life. As you navigate the exciting world of fabric transfer methods, understanding how to effectively implement DTF techniques can elevate your craft, ensuring high-quality results that captivate and impress. Let’s dive deeper into the mechanics of DTF printing and discover how we can harness its potential in our projects.

Understanding DTF Printing: A Comprehensive Overview

DTF printing stands for Direct-to-Film printing, a revolutionary approach that has transformed the landscape of custom apparel production. Unlike conventional printing methods like screen printing or sublimation, DTF utilizes a special film to print vibrant designs that can adhere to a variety of fabrics. This technique not only ensures high color vibrancy but also creates durable prints that can withstand washes without fading or cracking. The versatility of DTF printing allows it to be applied on cotton, polyester, and even blends, making it an attractive choice for both hobbyists and professional printers.

Furthermore, DTF transfers eliminate the limitations set by other printing methods, especially when it comes to fabric choice. While sublimation primarily works only on polyester, DTF opens the door to a wider range of textiles including dark and colored fabrics, which enhance creative possibilities. This ease of use and flexibility significantly aligns with the growing DIY culture, enabling individuals to create customized products that reflect their personal style with professional quality.

Key Equipment for Successful DTF Transfers

To achieve outstanding quality with DTF transfers at home, investing in the right equipment is crucial. At a minimum, you should have a high-quality heat press machine, as the accuracy in heat application will directly influence the adhesion and longevity of your prints. Additionally, a reliable DTF printer is essential; these printers are specifically designed to handle DTF inks, allowing for vibrant and detailed output.

Aside from the printer and heat press, you’ll also need DTF transfer film and adhesive powder, whose quantities depend on your printing scale. Understanding each machine’s specifications is vital. For instance, ensuring your printer can maintain the right ink flow and that your heat press can reach the necessary temperatures for your fabric type are critical for achieving professional results. With the right equipment in place, your home printing project is set to deliver amazing, vibrant results.

DIY DTF Printing: Step-by-Step Guide

Creating DTF transfers at home is a manageable process that anyone can master with a bit of practice and the right approach. Start by designing your graphics using software tools like Adobe Illustrator or even user-friendly options like Canva. Once your design is ready, print it onto the transfer film using your DTF printer, making sure to apply the correct settings for maximum quality.

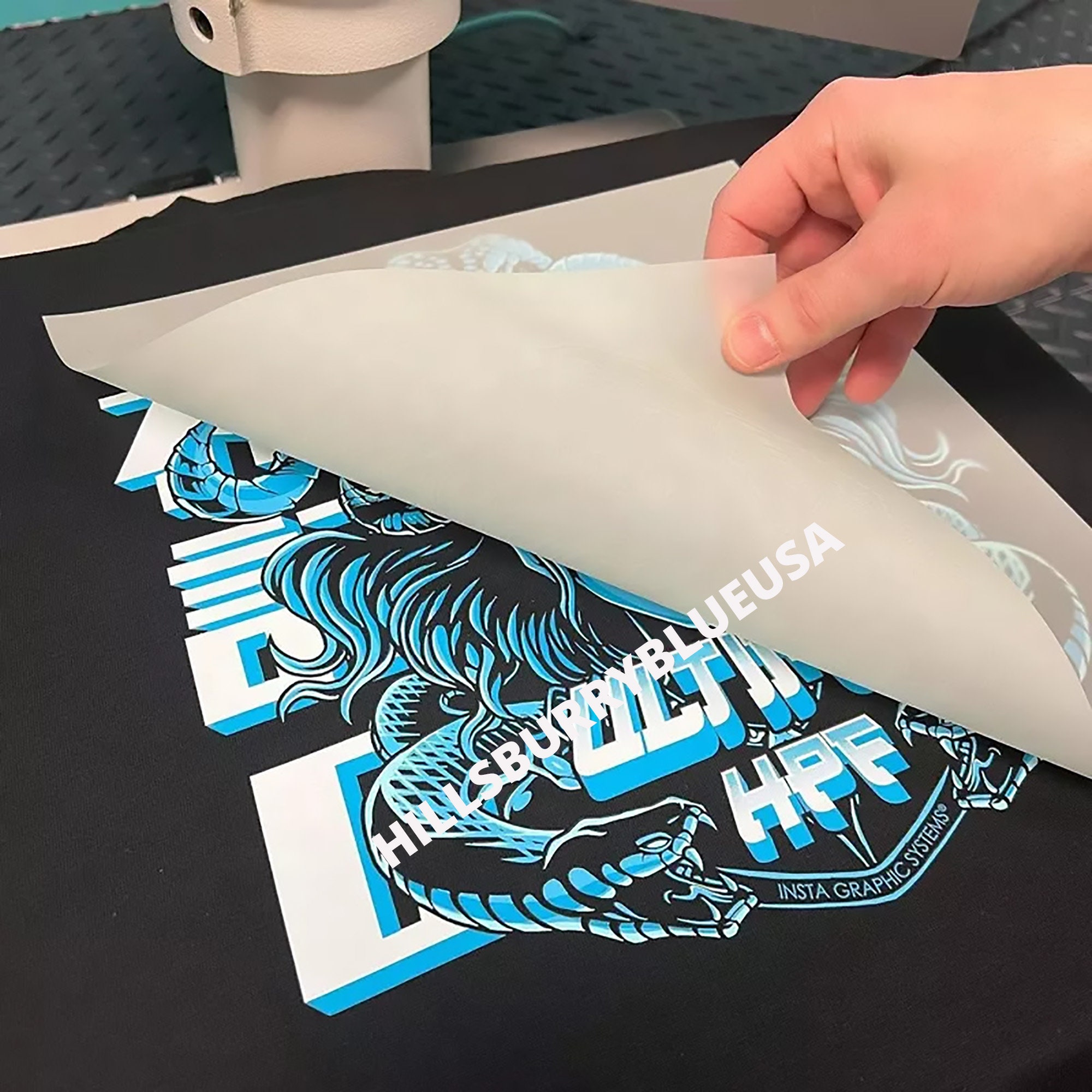

After printing, the next step involves applying the DTF adhesive powder to the printed film while it’s still wet. This powder will bind the ink to the fabric during the heat press process. Make sure to shake off any excess powder before pre-heating your heat press. Finally, set the appropriate temperature and pressure on your heat press and carefully place the film onto your chosen fabric, pressing down to achieve a flawless transfer. Remember to follow manufacturer instructions for optimal results.

Comparing DTF Transfers with Other Printing Methods

When it comes to custom apparel, DTF printing stands out in comparison to traditional methods like screen printing and sublimation. While screen printing requires separate screens for each color and is not suitable for intricate designs, DTF allows for full-color prints with no color limitations. Furthermore, DTF can be used on almost any fabric, providing a significant advantage over sublimation which predominantly works on polyester.

In addition to versatility, DTF printing is known for its durability, offering prints that withstand wear and tear, unlike other methods that may fade or crack over time. This resilience is essential for products that are frequently washed and used, making DTF a go-to option for both casual crafters and serious apparel brands alike.

The Growing Demand for DTF Transfers in the Market

The DTF printing industry has been witnessing a rapid surge in popularity recently, with projections indicating a remarkable annual growth rate of over 40%. This growth is primarily fueled by the increasing demand for high-quality custom apparel among consumers who seek personalized items for personal use or small businesses. The ease of use provided by recent technological advancements is making it easier than ever for home users to participate in this market.

Moreover, numerous companies are investing in user-friendly DTF printers and accessories, thus democratizing the ability to produce professional-quality prints at home. As more hobbyists take an interest in DTF printing, we can expect an influx of creative designs and innovative products to enter the market, further solidifying DTF technology’s presence in the custom apparel landscape.

Essential Heat Press Techniques for DTF Transfers

Mastering the heat application process is a crucial aspect of achieving successful DTF transfers. It’s important to adjust the heat press settings according to the type of fabric used and the specifications provided by the DTF transfer film manufacturer. Different materials have varying heat requirements; thus, getting familiar with each fabric type will help you avoid issues like scorching or inadequate adhesion.

Additionally, conducting test runs is a smart strategy, especially when trying out new fabrics or designs. Take the time to print multiple test samples, adjusting the temperature and pressure as necessary to pinpoint the ideal conditions for your specific project. Doing so will not only enhance your skills but will also result in a consistent output that showcases your designs beautifully.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a method of printing designs onto a special film which is then transferred to fabric using a heat press. This process involves printing with a DTF printer, applying an adhesive, and finally pressing the design onto various textiles, allowing for vibrant, durable prints.

How can I achieve professional quality DTF transfers at home?

To achieve professional quality DTF transfers at home, ensure you have a reliable DTF printer, a heat press machine, and high-quality transfer film. Create your designs using graphic software and properly calibrate your heat press settings for the type of fabric you’re working with.

What equipment is necessary for DIY DTF printing?

For DIY DTF printing, you will need a DTF printer, DTF transfer film, a quality heat press for DTF transfers, and DTF inks. Additionally, graphic design software will help you create your designs effectively.

What types of fabrics can I use with DTF transfers?

DTF transfers are compatible with a wide range of fabrics, including cotton, polyester, and cotton blends. This versatility allows users to print on dark fabrics, unlike other methods such as sublimation which primarily works on polyester.

Can DTF transfers be used for commercial printing?

Yes, DTF transfers are increasingly being used in commercial applications due to their versatility and ability to produce high-quality prints. Many small businesses are investing in DTF printing technology to expand their product offerings.

What tips can improve the heat application process for DTF transfers?

To improve the heat application process for DTF transfers, carefully adjust the temperature and duration on your heat press based on the fabric type. Performing test prints can help you find the perfect settings to achieve the best results.

| Key Features | Benefits | Essential Equipment | Recent Innovations | Market Trends |

|---|---|---|---|---|

| Vibrant Colors | Professional-quality designs at home | Heat press machine, DTF transfer film, compatible printer | User-friendly DTF printers like LOKLiK | Projected growth of over 40% annually |

| Versatile Material Compatibility | Durability of prints against washing | Graphic design software (e.g., Adobe Illustrator, Canva) | Trade services like Snuggle for custom transfers | Increase in commercial applications and DIY use |

| Adaptability to various fabrics (cotton, polyester) | Expands small business product offerings | Quality printer with DTF inks | Affordable products from companies like HTVRONT | Emergence of new companies in the market |

Summary

DTF transfers have transformed the landscape of fabric printing, enabling home users to achieve professional-quality results with ease. This method leverages cutting-edge technology to produce striking designs that are both vibrant and durable, making it suitable for a broad range of fabrics. As innovations in equipment and services proliferate, DIY enthusiasts and small businesses alike are given the tools they need to unleash their creativity, resulting in a robust growth trajectory for the DTF printing market. By leveraging essential tools and staying abreast of market trends, individuals can turn their imagination into tangible products, reinforcing the idea that high-quality fabric printing is achievable from the comfort of home.