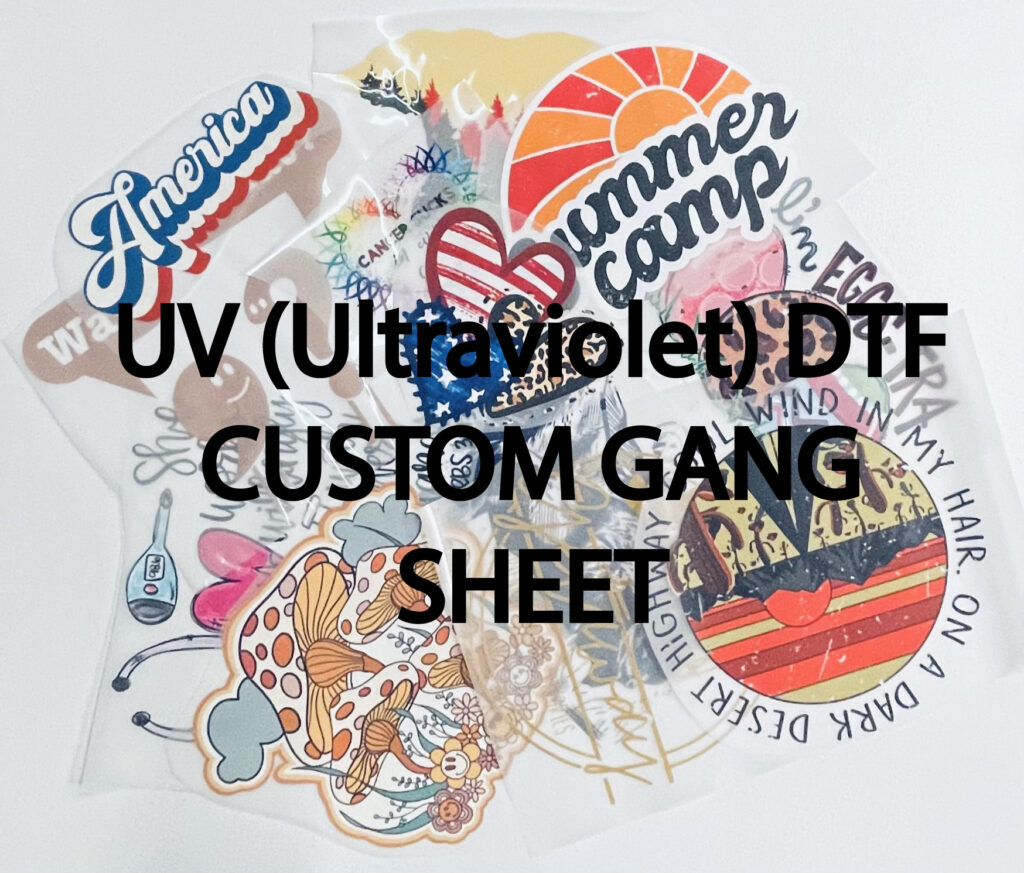

At the forefront of printing innovations is **UV DTF Gangheet**, an advanced technique that is reshaping how print shops operate today. This revolutionary process combines the principles of Direct to Film (DTF) printing with cutting-edge ultraviolet (UV) technology, allowing for stunning, high-quality outputs with minimal waste. By utilizing gang sheets, printers can efficiently produce multiple designs at once, maximizing both productivity and material usage. The instant drying capabilities of UV printing ensure that vibrant colors remain intact while minimizing lead times—a dream for businesses eager to meet customer demands swiftly. In this article, we’ll delve into the significance of UV DTF Gangheet, examining how recent advancements in this technology are setting new standards in the printing landscape.

Welcome to the cutting-edge world of UV DTF Gangheet, where innovative methods like Direct to Film printing and the dynamic gang sheet concept are revolutionizing the industry. This advanced printing solution merges traditional techniques with the benefits of UV curing, enhancing the quality and efficiency of print production. As demand for high-quality visuals grows, this technique allows designers and businesses to push creative boundaries while maintaining cost-effectiveness. By utilizing gang sheets, multiple designs can be printed simultaneously, significantly reducing waste and increasing throughput. Join us as we explore the implications of this technology and its potential to transform the printing landscape.

Understanding DTF Printing: A Game Changer in the Industry

Direct to Film (DTF) printing represents a revolutionary approach to the printing world, enabling designers and businesses to achieve vibrant and detailed graphics. This innovative method involves printing artwork on a special film that can be transferred onto a wide array of materials. The appeal of DTF printing lies in its cost-effectiveness, allowing for high-quality outputs without the need for extensive setup. As the printing landscape evolves, DTF continues to gain traction among Print Shops seeking efficient solutions.

What sets DTF apart from traditional printing methods is its ability to produce stunningly intricate designs with minimal ink wastage. Each film transfer can be reused multiple times, making it a sustainable option amid growing environmental concerns. With its rising popularity, businesses are increasingly adopting DTF technology to enhance their productivity and cater to the diverse needs of their clients.

The Gang Sheet Approach: Maximizing Efficiency and Cost-effectiveness

The concept of a gang sheet revolutionizes how print jobs are approached in DTF printing. By allowing multiple designs to be printed on a single sheet, companies can significantly reduce material waste, thus minimizing costs while maximizing output. This strategy not only optimizes ink and film usage but also accelerates production times, allowing businesses to meet customer demands more effectively.

Moreover, the gang sheet approach is particularly beneficial for high-volume orders. Print shops can efficiently manage their workflow, producing diverse designs in bulk without compromising on quality. The ability to quickly switch between different projects on a single sheet enhances flexibility, enabling businesses to respond to trends and remaining competitive in the dynamic market.

Integrating UV Technology: The Future of DTF Printing

The integration of ultraviolet (UV) technology with DTF printing marks a significant step forward in printing innovation. UV DTF Gangheet printing leverages the immediate curing power of UV light, which not only speeds up the drying process but also enhances the durability of prints. As UV ink is cured instantly, results are vibrant, resistant to fading, and exhibit excellent adhesion to various substrates.

This hybrid method combines the benefits of both worlds: the versatility of DTF printing and the robustness of UV technology. As more businesses adopt UV DTF techniques, they can deliver high-quality products faster, reinforcing their brand reputation and satisfying consumer demands for reliability and excellence.

Recent Innovations in UV DTF Printing Technology

Recent developments in UV DTF printing have sparked interest among pioneers in the industry. Companies are increasingly investing in high-capacity DTF printers capable of accommodating the additional complexities presented by UV curing processes. With these advancements, businesses can significantly enhance their production capabilities and efficiency, addressing the surging demand for quality print solutions.

Notably, innovative products such as the Anker eufyMake’s UV Printer E1 illustrate the potential of merging DTF and UV capabilities. This kind of technology allows smaller companies and hobbyists to tap into high-quality printing, expanding their creative possibilities and market reach. As these innovations unfold, we can expect newer solutions to emerge, pushing the boundaries of what’s possible in printing.

Exploring 3D Texturing in UV DTF Printing

The exploration of 3D texturing in UV DTF printing represents an exciting frontier in printing technology. By layering UV ink in specified patterns, companies can achieve stunning tactile outputs that add depth and dimension to printed materials. This innovation could open up new markets for unique product offerings and customization options, appealing to consumers looking for standout designs.

As the printing industry continuously seeks ways to attract customers through unique propositions, combining 3D texturing with traditional DTF processes can set businesses apart. This versatility not only enhances design creativity but also fosters a new wave of innovation that could revolutionize product branding and marketing strategies.

The Sustainability Edge of UV DTF Gangheet Printing

In an era where sustainability is paramount, adopting technologies like UV DTF gangheet printing aligns perfectly with eco-friendly practices. The efficient use of materials inherent in this printing method reduces waste, minimizing its ecological footprint. Fewer resources consumed in the printing process mean that businesses can operate more responsibly.

Moreover, UV DTF technology eliminates the need for harmful solvents and chemicals often found in traditional printing methods. By adhering to sustainable standards, companies not only appeal to environmentally-conscious consumers but also contribute positively to the planet, establishing themselves as leaders in responsible printing.

Frequently Asked Questions

What is UV DTF Gangheet printing and how does it differ from traditional DTF printing?

UV DTF Gangheet printing combines Direct to Film (DTF) printing and ultraviolet (UV) curing technology. Unlike traditional DTF printing, which relies solely on heat transfer, UV DTF technology cures the ink instantly using UV light, resulting in vibrant, durable prints that can be applied to a variety of surfaces.

What are the main benefits of using UV DTF Gangheet in printing?

The main benefits of UV DTF Gangheet include enhanced print durability due to UV curing, increased efficiency through gang sheet printing, flexibility in design options, and sustainability with reduced waste and material usage. This innovative approach enables faster production times while maintaining high-quality standards.

How does gang sheet printing improve the efficiency of UV DTF Gangheet production?

Gang sheet printing optimizes the use of materials by allowing multiple designs to be printed on a single sheet. This significantly reduces waste and lowers production costs, making UV DTF Gangheet printing a cost-effective solution for businesses with high-volume printing needs.

Can UV DTF Gangheet printing be used on multiple surfaces, and what are some examples?

Yes, UV DTF Gangheet printing offers versatility and can be used on various surfaces, including fabrics, wood, metal, and plastic. This makes it an excellent choice for creating custom products such as apparel, promotional items, and signage.

What advancements have been made in UV DTF Gangheet technology recently?

Recent advancements in UV DTF Gangheet technology include the development of high-capacity DTF printers like those from EazyDTF, innovations such as the Anker UV Printer E1, and the exploration of 3D texturing capabilities, enhancing both the efficiency and creative possibilities in printing.

What sustainability benefits are associated with UV DTF Gangheet printing?

UV DTF Gangheet printing supports sustainability by minimizing material waste through gang sheet production and promoting efficient use of resources. The UV curing process also reduces the need for solvents, making it a greener option for businesses committed to eco-friendly practices.

| Key Point | Description |

|---|---|

| Introduction | Overview of UV DTF Gangheet as an innovative printing technology combining DTF and UV curing. |

| What is DTF Printing? | A method for printing vibrant graphics on film for transfer to various surfaces. |

| The Gang Sheet Concept | Printing multiple designs on one sheet to optimize material use and reduce costs. |

| Enter UV Printing Technology | Uses UV light for instant ink curing, resulting in vibrant, durable prints. |

| Key Developments | Investments in DTF technology and innovations like the Anker UV Printer E1 are driving advancements. |

| Benefits of UV DTF Gangheet | Includes efficiency, flexibility, durability, and sustainability in printing. |

Summary

UV DTF Gangheet technology is a revolutionary advancement in the printing industry that combines the best features of Direct to Film (DTF) and ultraviolet (UV) printing. This innovative method not only enhances efficiency and reduces costs through the use of gang sheets, but it also offers exceptional print durability and vibrant color applications. The ongoing developments in this technology, including significant investments from leading companies and the introduction of advanced printers like the Anker UV Printer E1, signal a promising future for high-quality print production. As businesses increasingly adopt UV DTF Gangheet techniques, they position themselves at the cutting edge of printing innovation, ready to meet evolving market demands and overcome sustainability challenges.